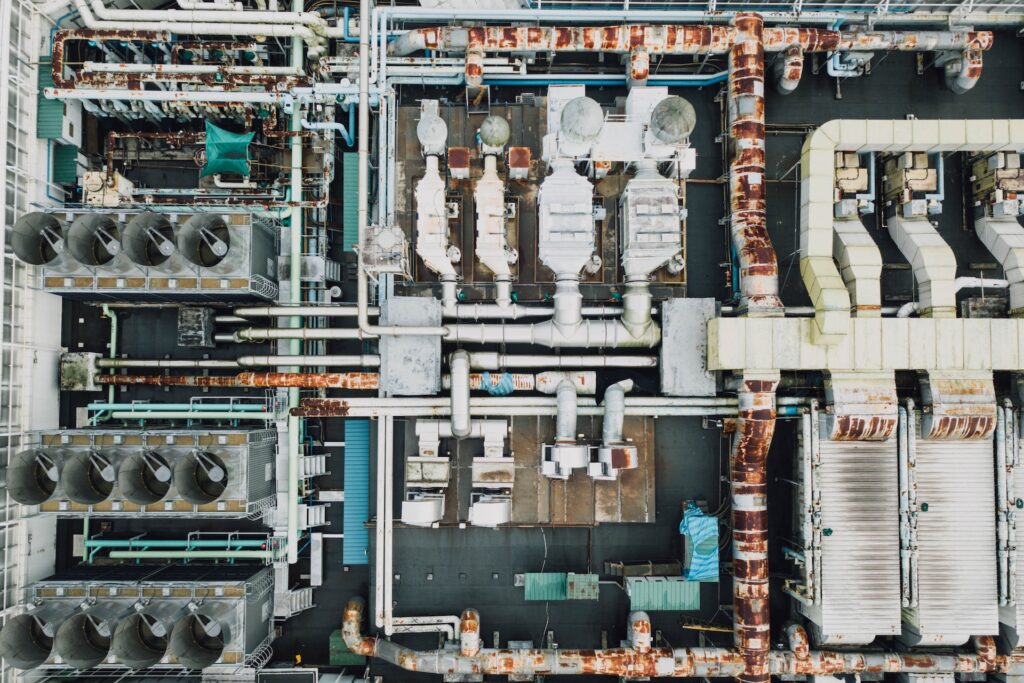

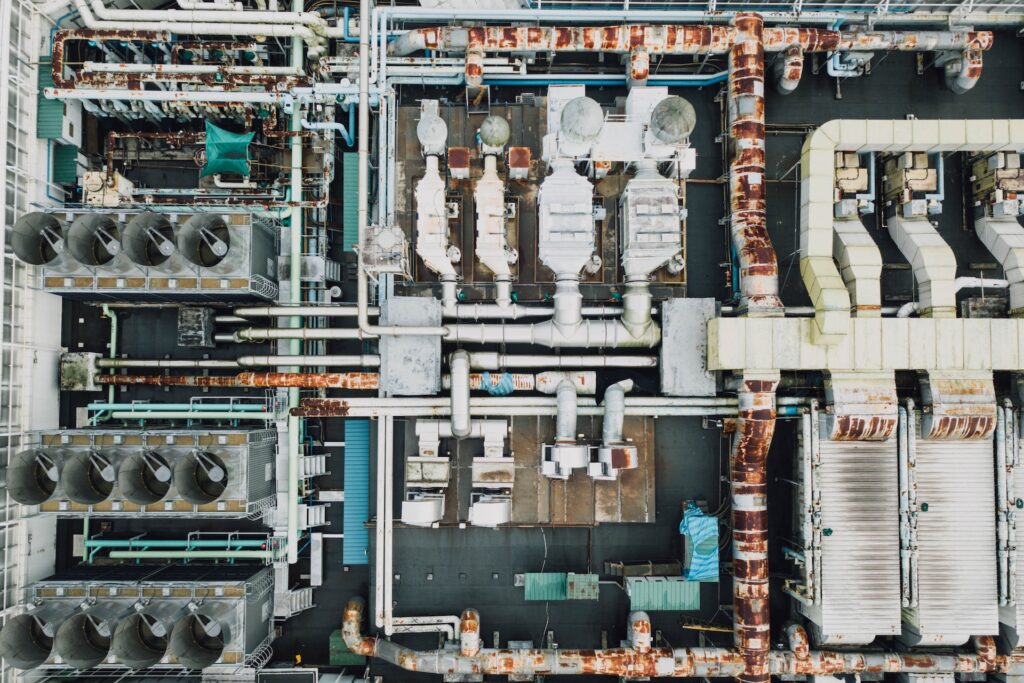

Most of our work is helping oil, gas and chemical plants implement Human Factors to comply with regulations, adopt best practices, improve human reliability, have less downtime and improve efficiencies.

Most of our work is helping oil, gas and chemical plants implement Human Factors to comply with regulations, adopt best practices, improve human reliability, have less downtime and improve efficiencies.

Most of our work is helping oil, gas and chemical plants implement Human Factors to comply with regulations, adopt best practices, improve human reliability, have less downtime and improve efficiencies. The organisations we work with might be completely new to Human Factors, need some training, and a plan of action; they might be long-term clients who have an ongoing programme of work with us; or clients who need help and guidance on developing policies and their internal capability.

“Where reliance is placed on people (to prevent major accidents), human factors and human reliability should be addressed with the same rigour as technical and engineering measures.”

UK Health & Safety Executive (HSE)

Most of our work is helping oil, gas and chemical plants implement Human Factors to comply with regulations, adopt best practices, improve human reliability, have less downtime and improve efficiencies. The organisations we work with might be completely new to Human Factors, need some training, and a plan of action; they might be long-term clients who have an ongoing programme of work with us; or clients who need help and guidance on developing policies and their internal capability.

“Where reliance is placed on people (to prevent major accidents), human factors and human reliability should be addressed with the same rigour as technical and engineering measures.”

UK Health & Safety Executive (HSE)

The oil, gas and chemicals sectors have quite a mature and structured approach to applying Human Factors. For example, the UK’s Human Factors Delivery Guide for COMAH sites and the more recent guide for managing Human Factors offshore propose several topic areas to improve human reliability and optimise human performance. Our services and experience are aligned with these key Human Factors topic areas.

SCTA is a proactive approach to Human Factors risk assessment. We developed some of the foundational ideas of this methodology before it was required by the regulators and considered best practices. We can provide one-off analyses, a programme of work, or help to develop in-house capability. Our SHERPA Software is specifically designed to do the heavy lifting of SCTA work.

Incidents can be costly for the organisation and life-changing for the individuals involved. We want to maximise the learning from incidents and near misses, going beyond retraining and blaming staff, and adding another check. We do not believe people should be fixated on establishing a root cause. Instead, we can provide guidance on taking a systems approach to explore the contributory factors and to learn as much as possible from an incident.

Non-compliance with procedures is cited as one of the key contributory factors to accidents. Operators are not helped when procedures are wrong, out of date, too lengthy, poorly formatted and unusable. Our tools and methods ensure that procedures have the right content, that critical steps are highlighted and that they are in a usable format. The SHERPA Software provides an intuitive and powerful Task Analysis engine and can produce auto-formatted procedures at the click of a button.

We take a systematic approach to ensure that staff intending to conduct critical tasks have the required competence to do critical task steps correctly. This is different to attending generic training that lacks nuance and different to on-the-job training which can be unreliable. Instead critical task steps are identified, and the knowledge and skill requirements for those steps are specified, which provides extra assurance that the most critical steps are performed well.

Handovers and Permit To Work (PTW) systems are of key interest in the Process Industries. Piper Alpha is perhaps one of the strongest reminders of what can go wrong when these systems let people down. We can provide guidance and assessment on Critical Communications in these areas, and part of critical task performance.

How information is presented and relayed in control panels and Human-Machine Interface (HMI) could influence the ability of operators to make quick and informed decisions during task operations. We can help you evaluate the overall process design and advise on improvements to ensure that the design is optimised to fit the users’ needs and aligned with the UK’s HSE Human Factors Delivery Guide.

Organisational issues such as workload and fatigue can contribute to an individual’s capability to perform effectively. We understand that these issues can be challenging for organisations and are able to support sites in managing their workload via our SHERPA software. We are also able to offer our consultancy services in this area.

Management of Change (MoC) is a systematic approach that is used by organisations to plan, manage and implement any organisational changes. During this process, Human Factors should be considered as this can help ensure a smooth transition, enhance work efficiency, and minimise the risk of potential harm on site. Our highly experienced consultants can offer their expertise in integrating Human Factors during this process, and to help address any concerns or issues that may arise.

The success and efficiency of an organisation rely on a balance between the behaviour, capability and well-being of its people. Our Human Performance Leadership workshops are built on the foundation that leaders are vital in encouraging a culture and environment where people feel supported to perform their duties, empowered to share their opinions, and motivated to grow and improve.

One of the first things a HSE inspector might want to see when conducting a Human Factors review is the policy documentation that outlines what should be done. We can assess and help develop such documentation for different HF Topic areas.

For example, we helped a client develop policy and guidance documents to embed Safety Critical Task Analysis (SCTA) at their site.

We worked together on SCTA activities, including an exercise on identifying and prioritising COMAH-critical tasks, and an SCTA workshop on a critical task. Additionally, some of the people from site attended our SCTA course to consolidate their learning.

We collaborated with the site to develop guidance documents that served to act as a benchmark for carrying out SCTAs in a manageable and sustainable manner. An example from the document developed was a standard for assuring human performance that outlines the competency requirements, the roles and responsibilities, and the actions to be taken related to the SCTA process.

One of the first things a HSE inspector might want to see when conducting a Human Factors review is the policy documentation that outlines what should be done. We can assess and help develop such documentation for different HF Topic areas.

For example, we helped a client develop policy and guidance documents to embed Safety Critical Task Analysis (SCTA) at their site.

We worked together on SCTA activities, including an exercise on identifying and prioritising COMAH-critical tasks, and an SCTA workshop on a critical task. Additionally, some of the people from site attended our SCTA course to consolidate their learning.

We collaborated with the site to develop guidance documents that served to act as a benchmark for carrying out SCTAs in a manageable and sustainable manner. An example from the document developed was a standard for assuring human performance that outlines the competency requirements, the roles and responsibilities, and the actions to be taken related to the SCTA process.

We were approached with a request to carry out a Safety Critical Task Analysis (SCTA) on starting an induction furnace.

Prior to the SCTA workshop, we used the SOP to develop an initial task analysis in the SHERPA software, and to identify potential high-risk actions and issues in the task analysis. We reviewed and developed this analysis with a multi-disciplinary team in the workshop.

We identified improvements that may benefit the site. One of them was to optimise the Human-Machine Interface (HMI) by adding some prompts and redesigning the screen so that it would help with the user experience. Prompts are a useful way to direct the operators’ attention to the screen as it requires them to take action to progress the task. Furthermore, we suggested some ways to include more visual feedback that would help the operators understand the status of the induction furnace. By including more salient cues like installing lights that reflect the induction furnace’s state, this provides the operator and the team the opportunity to build a mental model of the task, which will help reduce the likelihood of error. We also discussed limiting the energy provided to the induction furnace to reduce the chance of a super heat event. Overall, the analysis received a positive response from the site and they were keen to implement the actions suggested.

We were approached with a request to carry out a Safety Critical Task Analysis (SCTA) on starting an induction furnace.

Prior to the SCTA workshop, we used the SOP to develop an initial task analysis in the SHERPA software, and to identify potential high-risk actions and issues in the task analysis. We reviewed and developed this analysis with a multi-disciplinary team in the workshop.

We identified improvements that may benefit the site. One of them was to optimise the Human-Machine Interface (HMI) by adding some prompts and redesigning the screen so that it would help with the user experience. Prompts are a useful way to direct the operators’ attention to the screen as it requires them to take action to progress the task. Furthermore, we suggested some ways to include more visual feedback that would help the operators understand the status of the induction furnace. By including more salient cues like installing lights that reflect the induction furnace’s state, this provides the operator and the team the opportunity to build a mental model of the task, which will help reduce the likelihood of error. We also discussed limiting the energy provided to the induction furnace to reduce the chance of a super heat event. Overall, the analysis received a positive response from the site and they were keen to implement the actions suggested.

Shutdowns and turnarounds (TARs) occur when a section of the plant is scheduled for maintenance or a project. During this time, there is a likelihood that the plant could experience an increased risk of process safety incidents. This is because the plant will undergo several maintenance operations which may be infrequently performed, and there could be increased pressure on the staff due to the high workload and time pressure to complete the activities.

Given the high complexity of TARs, we screened TAR tasks by ranking safety-critical tasks based on the chances of a Major Accident Hazard (MAH) scenario, and then rating these MAH-related tasks against the existing engineering controls and its vulnerability. Following the screening, we carried out an SCTA to identify any HF-related issues and suggested improvements to mitigate the risk of any incidents.

The workshop highlighted several issues that sites should be aware of during TARs. An example of this was that the procedures used should minimise any unnecessary operator movements as means of preventing any personal injury. Sites should also ensure that there are sufficient individuals and equipment available to perform the tests and that the individuals are well trained and capable of performing these tests.

Shutdowns and turnarounds (TARs) occur when a section of the plant is scheduled for maintenance or a project. During this time, there is a likelihood that the plant could experience an increased risk of process safety incidents. This is because the plant will undergo several maintenance operations which may be infrequently performed, and there could be increased pressure on the staff due to the high workload and time pressure to complete the activities.

Given the high complexity of TARs, we screened TAR tasks by ranking safety-critical tasks based on the chances of a Major Accident Hazard (MAH) scenario, and then rating these MAH-related tasks against the existing engineering controls and its vulnerability. Following the screening, we carried out an SCTA to identify any HF-related issues and suggested improvements to mitigate the risk of any incidents.

The workshop highlighted several issues that sites should be aware of during TARs. An example of this was that the procedures used should minimise any unnecessary operator movements as means of preventing any personal injury. Sites should also ensure that there are sufficient individuals and equipment available to perform the tests and that the individuals are well trained and capable of performing these tests.

A site had recently undergone changes in staffing arrangements and requested our assistance in reviewing the potential impact on emergency response.

We worked with the site’s team to understand the current staffing arrangements and discuss some of the potential MAH scenarios and their emergency responses. Following this, we organised several workshops to assess the identified scenarios. We approached the analysis using the CRR 348/2001 method, which involved a series of decision trees to ascertain the probability of a successful response to an emergency, and a general assessment of HF issues such as fatigue, situational awareness, teamwork etc.

Suggestions for improvement included improving the Hierarchy of Controls (HoC) to reduce the reliance on the operator, reviewing the work arrangements to prevent fatigue (e.g., shift cover, shift management, and break times), and clarifying the competence management system (e.g., minimum competency requirements, procedures for training, training requirement etc.). Finally, we suggested that the site should review the Management of Change (MoC) procedures to promote engagement with the multiple stakeholders that would be affected by such changes.

A site had recently undergone changes in staffing arrangements and requested our assistance in reviewing the potential impact on emergency response.

We worked with the site’s team to understand the current staffing arrangements and discuss some of the potential MAH scenarios and their emergency responses. Following this, we organised several workshops to assess the identified scenarios. We approached the analysis using the CRR 348/2001 method, which involved a series of decision trees to ascertain the probability of a successful response to an emergency, and a general assessment of HF issues such as fatigue, situational awareness, teamwork etc.

Suggestions for improvement included improving the Hierarchy of Controls (HoC) to reduce the reliance on the operator, reviewing the work arrangements to prevent fatigue (e.g., shift cover, shift management, and break times), and clarifying the competence management system (e.g., minimum competency requirements, procedures for training, training requirement etc.). Finally, we suggested that the site should review the Management of Change (MoC) procedures to promote engagement with the multiple stakeholders that would be affected by such changes.

This involved two Human Factors Safety Critical Task Analysis (SCTA) studies: 1) the first was on a process concerned with the inadvertent charging of drummed materials, 2) the second was on a process concerned with the inadvertent charging of bags of powdered materials. Essentially, mixing materials that could lead to a major event.

Read about our process and results;

This involved two Human Factors Safety Critical Task Analysis (SCTA) studies: 1) the first was on a process concerned with the inadvertent charging of drummed materials, 2) the second was on a process concerned with the inadvertent charging of bags of powdered materials. Essentially, mixing materials that could lead to a major event.

Read about our process and results;

Assessment of operating procedure provision and development of a procedures design manual with an associated two-day course in procedure design.

Permit to Work

Permit to Work

Permit to Work

Human Factors & Safety Analysis in the Chemical Industry

Human factors in safety management as demonstrated in their COMAH submission.

Methods used for reporting and investigating incidents, and their effectiveness in addressing human factors.

Human Factors & Safety Analysis in the Chemical Industry

Human factors analysis of a computerised process control system and development of generic human factors design guidelines.

Human Factors & Safety Analysis in the Chemical Industry

Development of a practical systems-based approach to optimise human performance in upstream chemical operations.

Human Factors & Safety Analysis in the Chemical Industry

Development of a methodology to identify critical human interactions with plants.

Human Factors & Safety Analysis in the Chemical Industry

Practical application of the technique developed for Exxon Research (see above) to various chemical process operations.

Human Factors & Safety Analysis in the Chemical Industry

Analysis of operator workload and error rates in chemical plant control.

Human Factors & Safety Analysis in the Chemical Industry

Assessment of design factors affecting mental workload in process plants.

Human Factors & Safety Analysis in the Chemical Industry

Application of the Systematic Critical Human Error Management Approach (SCHEMA) to a case study of a chemical plant operation.

Human Factors & Safety Analysis in the Offshore Industry

Human Factors assessment of an offshore control centre.

Safety analysis of satellite wire-lining operations.

Human Factors & Safety Analysis in the Offshore Industry

Safety assessment of the launch of a free fall lifeboat.

Human Factors & Safety Analysis in the Offshore Industry

Human reliability assessment of a chlorine handling operation.

Development of a methodology to assess human factors in offshore safety cases (Offshore Safety Directorate)

Specialist Training

Development of training and job aid support to allow improved handling of process disturbances.

Specialist Training

Development of training and job aid support to allow improved handling of process disturbances.

Specialist Training

Development of training and job aid support to allow improved handling of process disturbances.

Specialist Training

User Specification and Development

Design of user specification for computer-based process management systems.

Assessment of operating procedure provision and development of a procedures design manual with an associated two-day course in procedure design.

Permit to Work

Permit to Work

Permit to Work

Human Factors & Safety Analysis in the Chemical Industry

Human factors in safety management as demonstrated in their COMAH submission.

Methods used for reporting and investigating incidents, and their effectiveness in addressing human factors.

Human Factors & Safety Analysis in the Chemical Industry

Human factors analysis of a computerised process control system and development of generic human factors design guidelines.

Human Factors & Safety Analysis in the Chemical Industry

Development of a practical systems-based approach to optimise human performance in upstream chemical operations.

Human Factors & Safety Analysis in the Chemical Industry

Development of a methodology to identify critical human interactions with plants.

Human Factors & Safety Analysis in the Chemical Industry

Practical application of the technique developed for Exxon Research (see above) to various chemical process operations.

Human Factors & Safety Analysis in the Chemical Industry

Analysis of operator workload and error rates in chemical plant control.

Human Factors & Safety Analysis in the Chemical Industry

Assessment of design factors affecting mental workload in process plants.

Human Factors & Safety Analysis in the Chemical Industry

Application of the Systematic Critical Human Error Management Approach (SCHEMA) to a case study of a chemical plant operation.

Human Factors & Safety Analysis in the Offshore Industry

Human Factors assessment of an offshore control centre.

Safety analysis of satellite wire-lining operations.

Human Factors & Safety Analysis in the Offshore Industry

Safety assessment of the launch of a free fall lifeboat.

Human Factors & Safety Analysis in the Offshore Industry

Human reliability assessment of a chlorine handling operation.

Development of a methodology to assess human factors in offshore safety cases (Offshore Safety Directorate)

Specialist Training

Development of training and job aid support to allow improved handling of process disturbances.

Specialist Training

Development of training and job aid support to allow improved handling of process disturbances.

Specialist Training

Development of training and job aid support to allow improved handling of process disturbances.

Specialist Training

User Specification and Development

Design of user specification for computer-based process management systems.

This video demonstrates the use of the SHERPA methodology and software, which until recently was called the Human Factors Risk Manager. This shows how we can develop a detailed task analysis, how we can predict potential errors in the task, and identify factors influencing the likelihood of those errors.

This video demonstrates the use of the SHERPA methodology and software, which until recently was called the Human Factors Risk Manager. This shows how we can develop a detailed task analysis, how we can predict potential errors in the task, and identify factors influencing the likelihood of those errors.

Contact us today to discuss how our services can improve human factors in aviation operations and drive continuous improvement in human performance.

Get the latest newsletter by signing-up today

This free 30 minute mini-course will introduce you to Human Factors, and how critical task reviews are used to improve the quality and safety of tasks and processes across different industries.

It’s free, informative and you’ll even get a certificate of completion.

This short and engaging handbook provides a great overview of Human Factors Systems Critical Task Analysis (SCTA) and how it helps people across sectors reduce error and improve human performance.

SCTA can help keep people safe and delivers value.

Popular Pages

© Human Reliability 2025.

1 School House, Higher Lane,

Dalton, Lancashire,

WN8 7RP, UK.

T: +44 (0) 1257 463 121

E: [email protected]